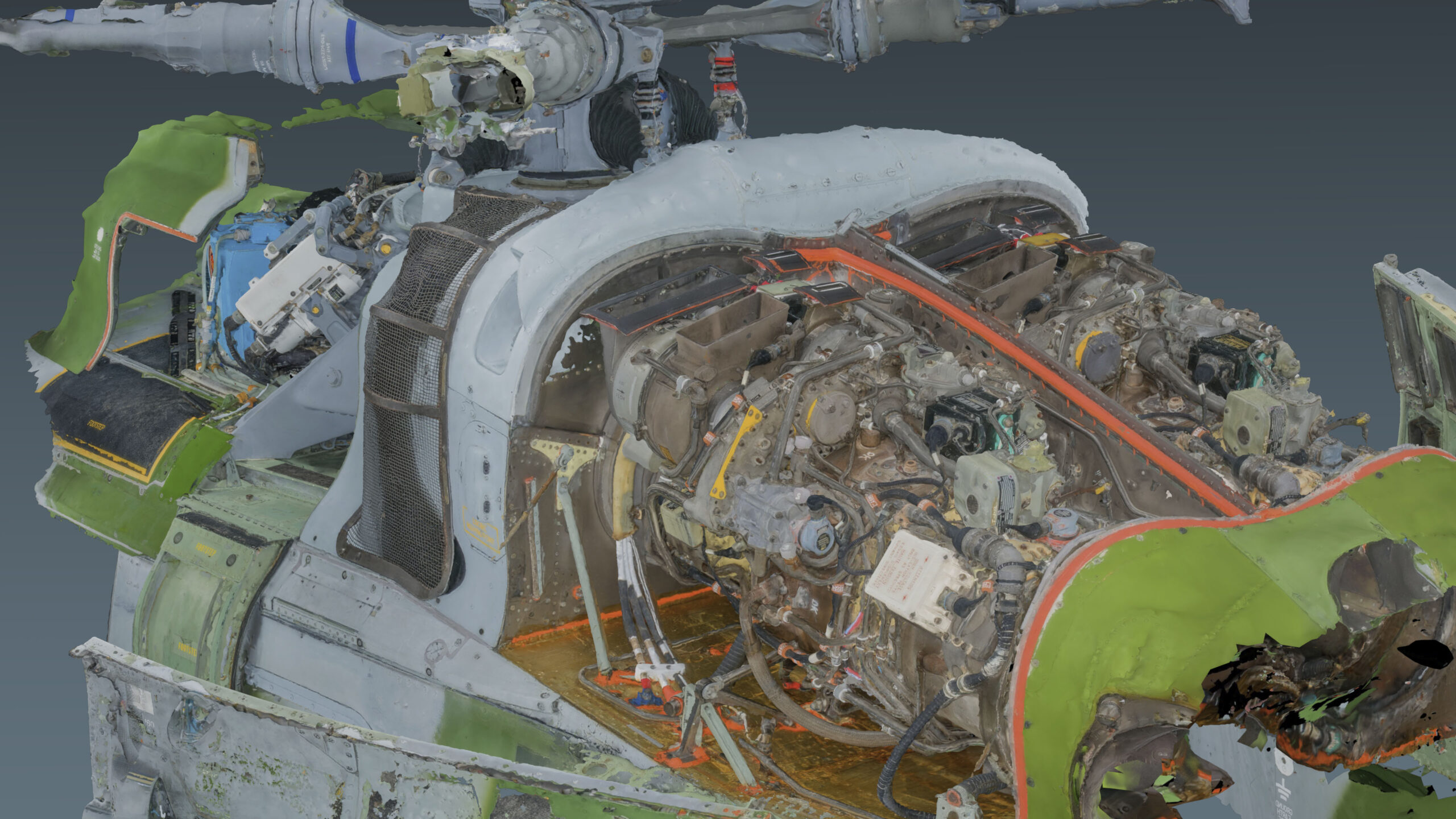

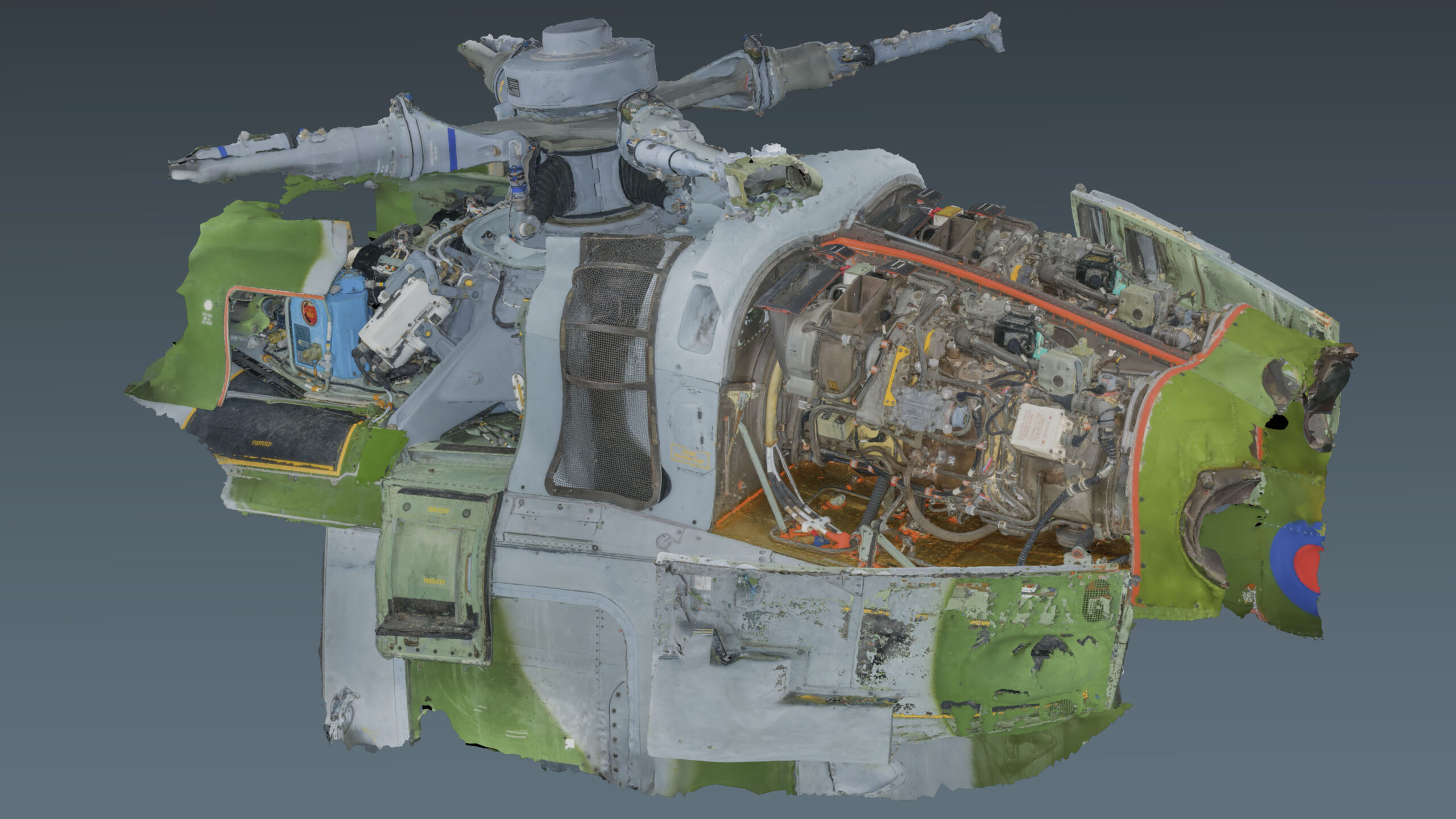

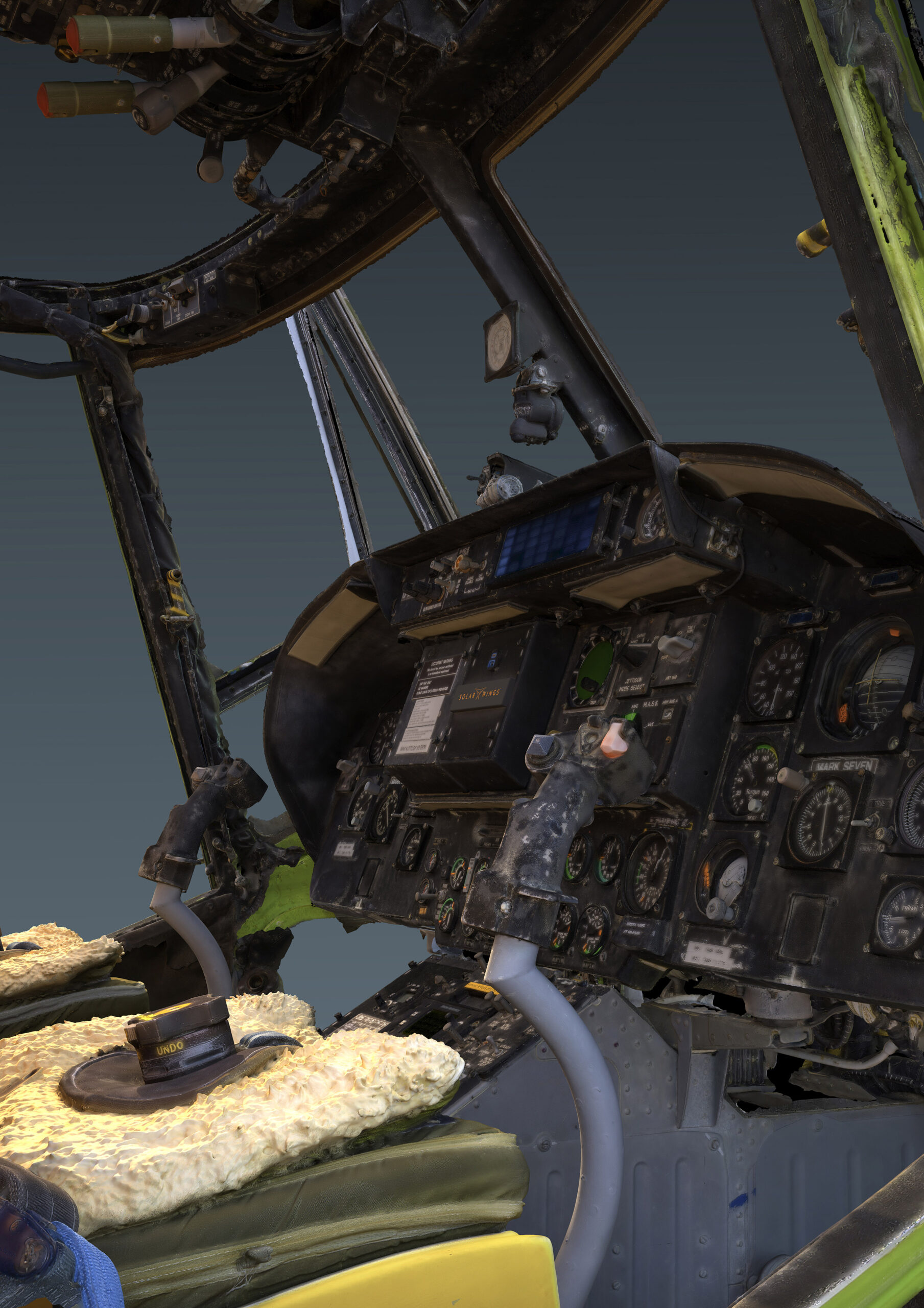

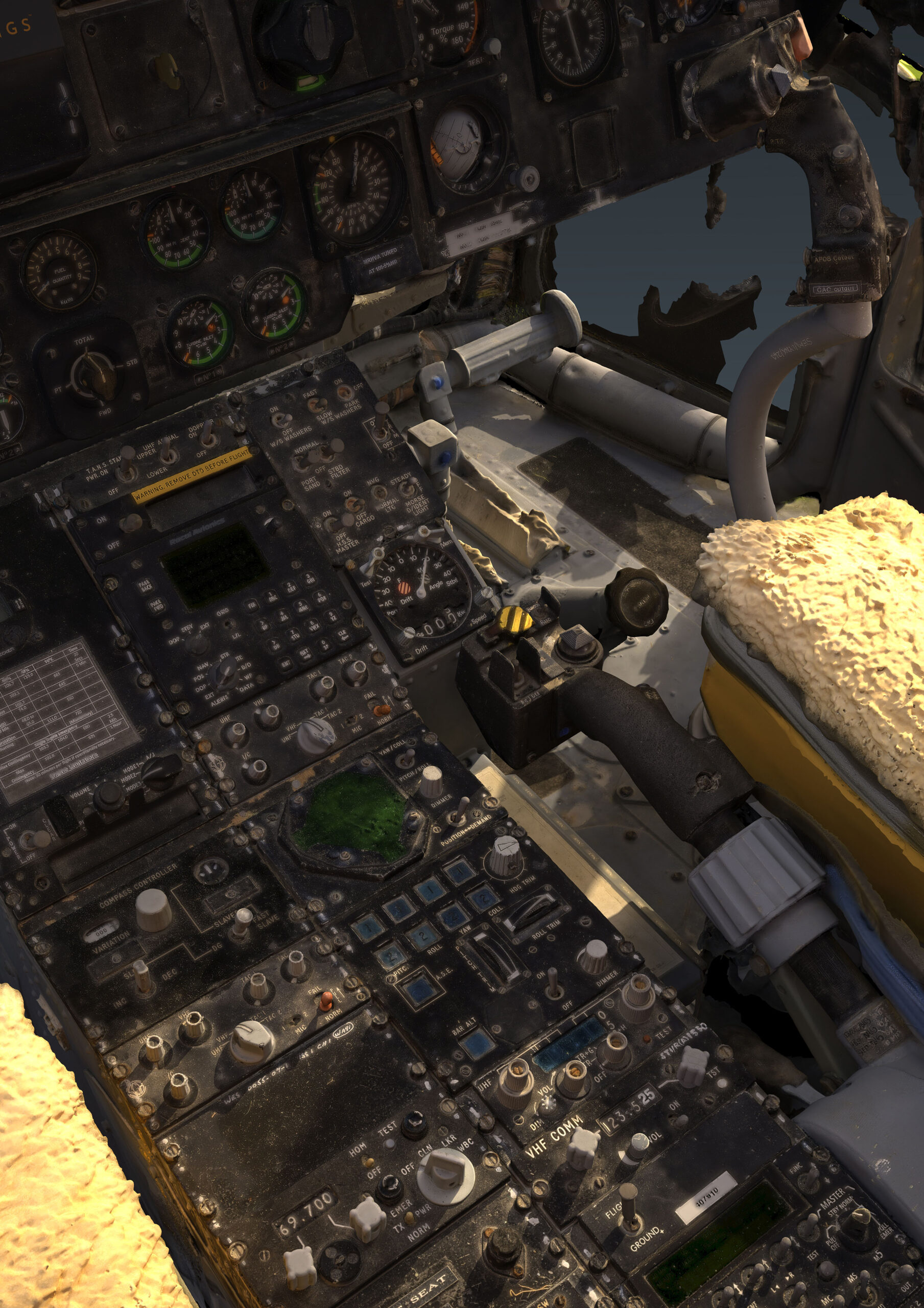

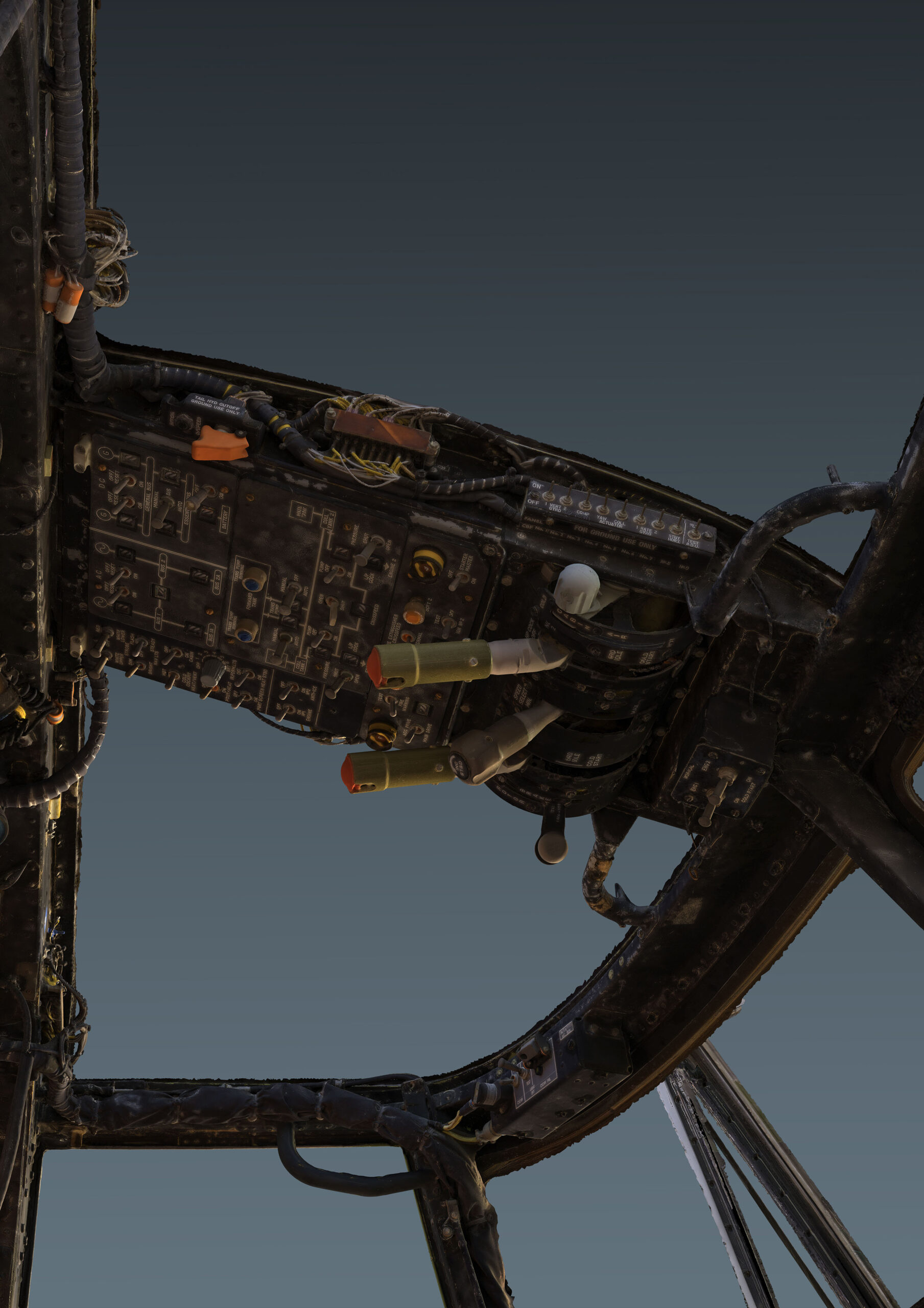

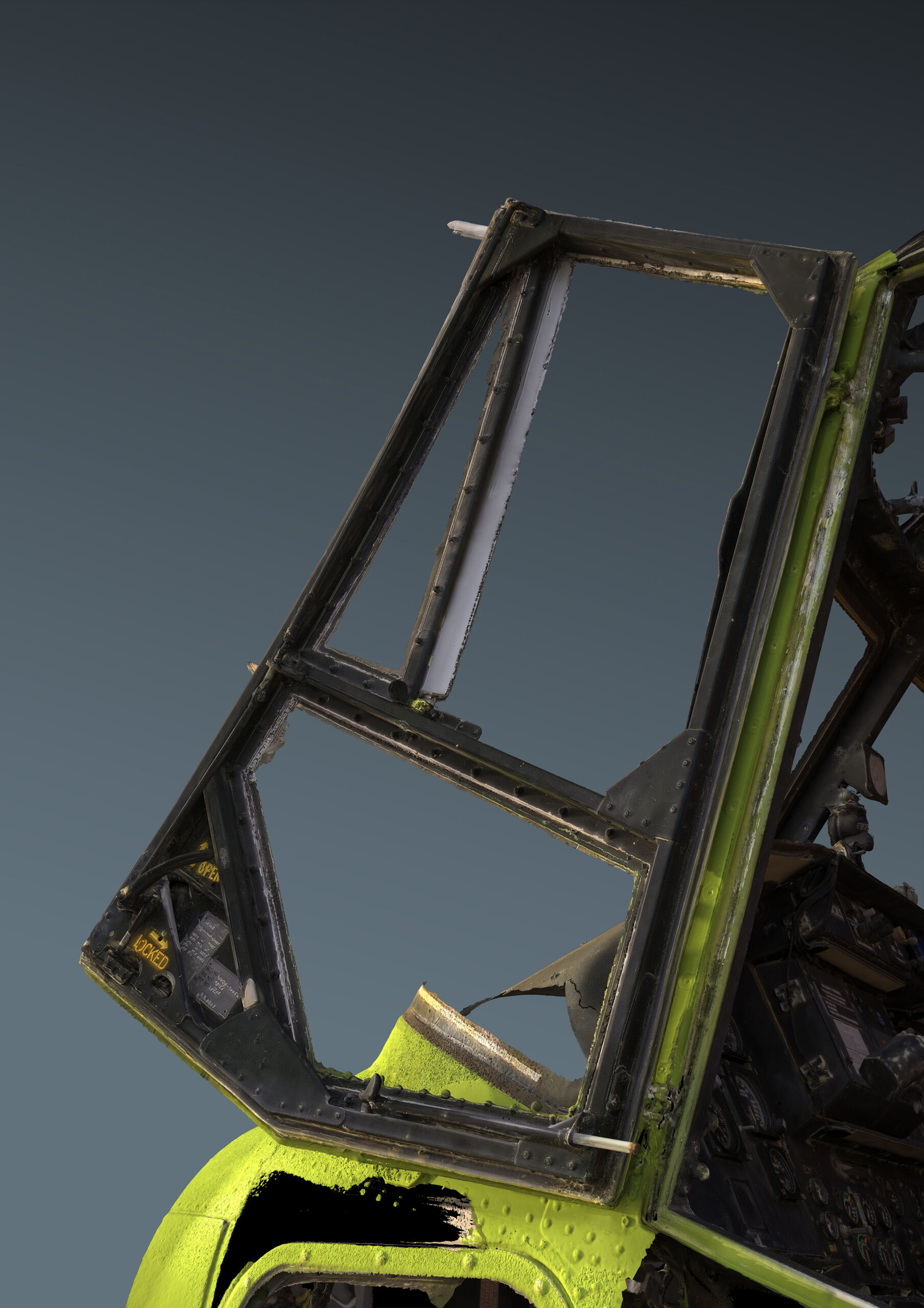

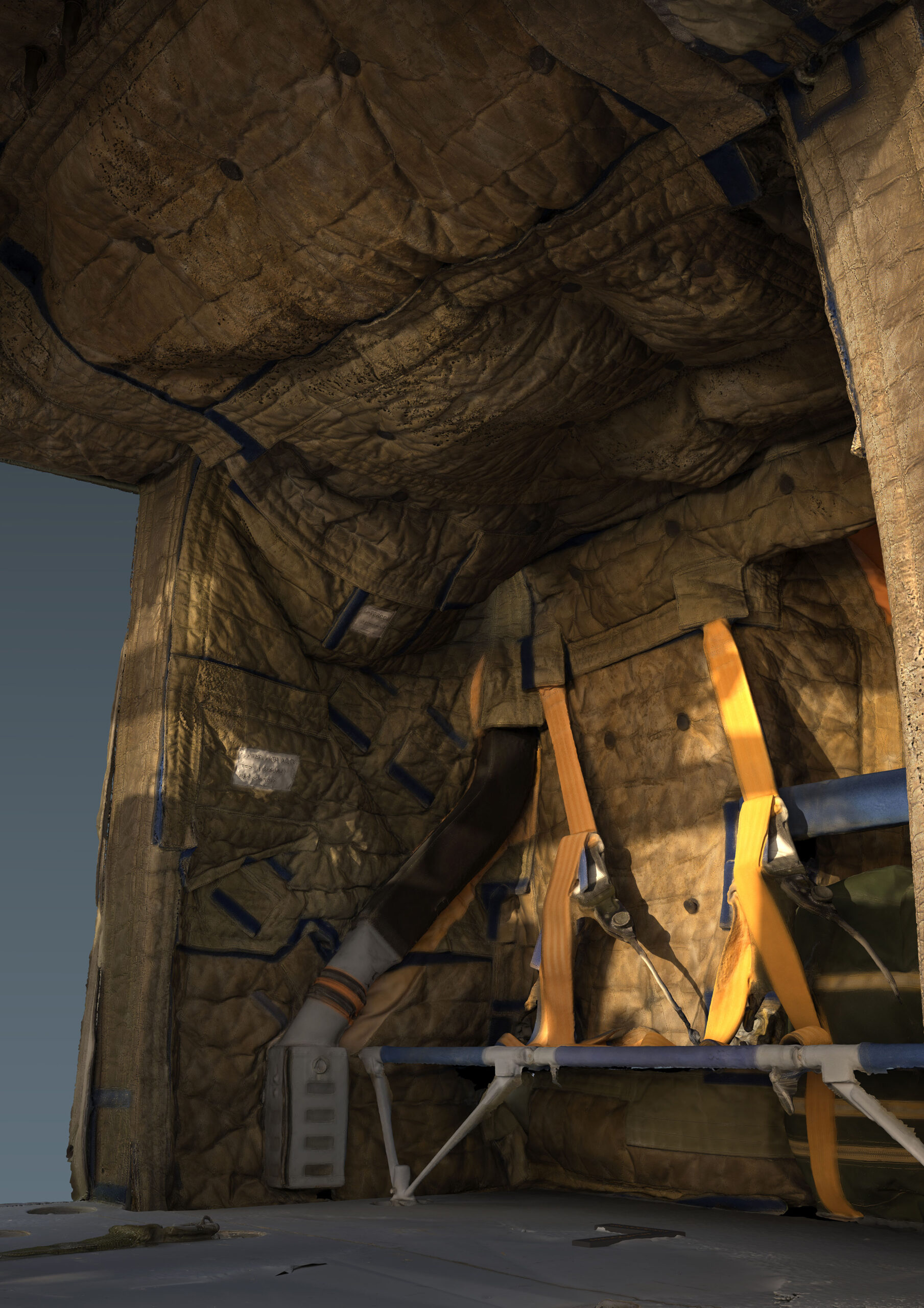

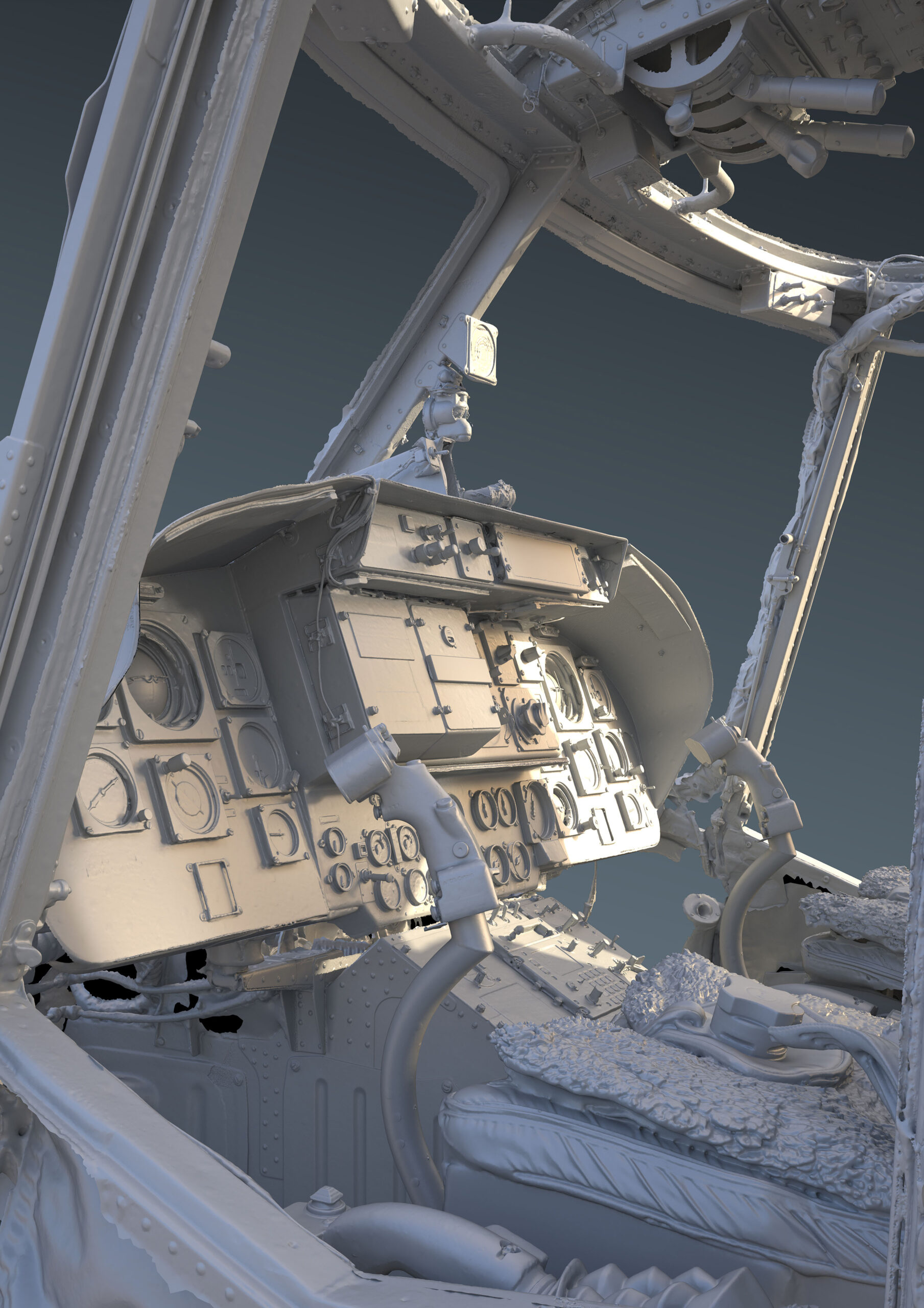

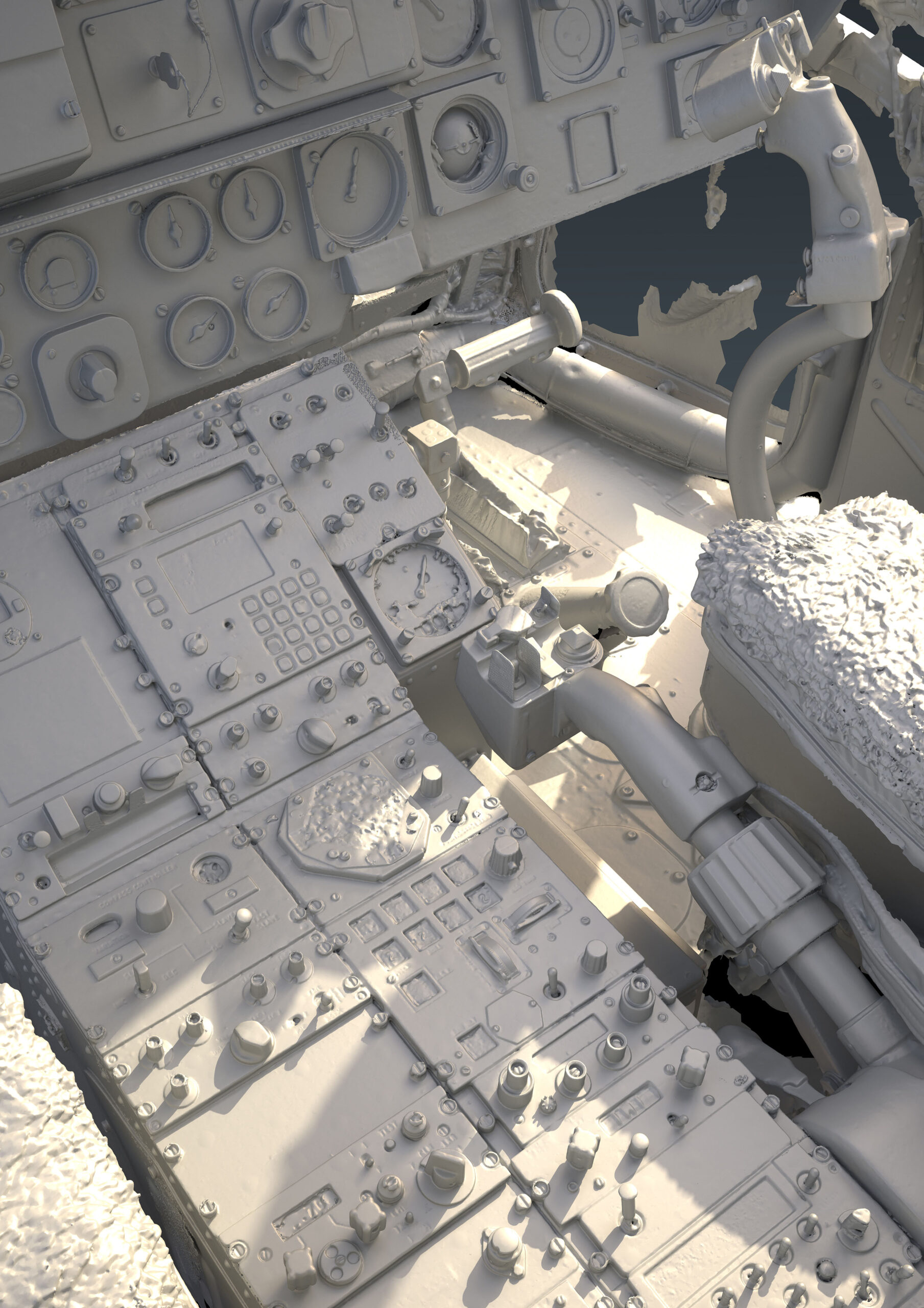

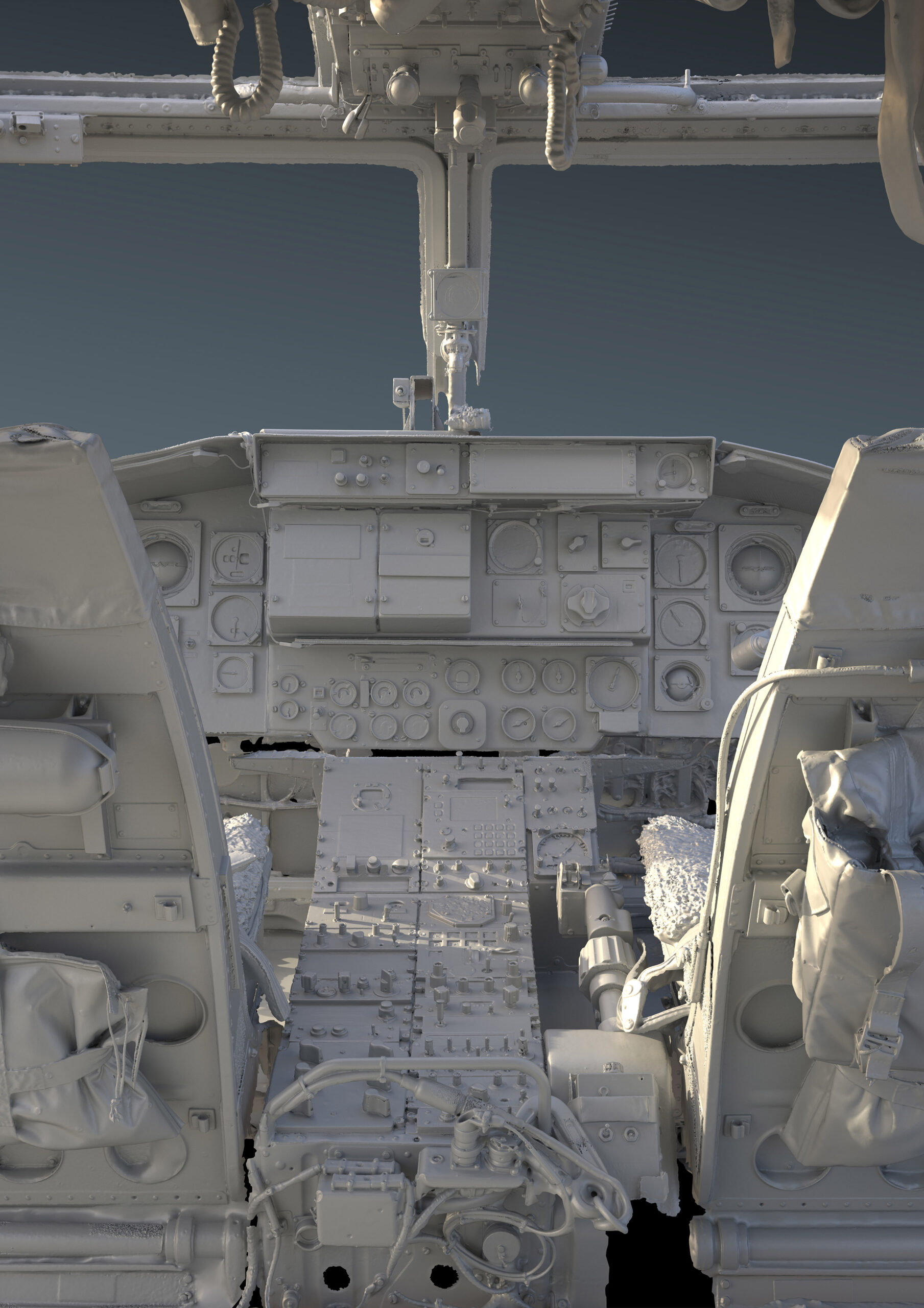

AH-7 Lynx – 3D Scanning

Task: 3D Scanning

Purpose of creation: Data capture for flight simulator

In December 2024 one of my clients wanted me to scan the Ah-7 Lynx helicopter for his new project. After one month of preparation, purchase of the new equipment, and its tests for the new workflow, I went to the 3D scanning of the AH-7 Lynx in England. The 3D scanning lasted in total for 16 days.

Ah-7 Lynx arrived a couple of days late from its initially planned annual maintenance, and the initial plan for the shoot had to be cramped. As soon as Lynx returned I began the 3D scanning, which lasted for 10 active days. During the 3D scanning, I had to work an average of 17.5 hours a day. The 3D scanning happened during the opening hours of the hanger, and the processing of data happened every evening. Everything had to be processed every day after the scanning, this was necessary to be aware of what needed to be scanned on the next day. It was the most intense 3D scanning I had to date, and planning had to be changed on an hourly basis.

As a result, my planned return flight was affected by the maintenance delays of the Ah-7 Lynx, the overwork hours could not save it from the shift to the next possible date. During the shoot two data points were captured in their highest detail – model & texture.

Graham, the owner of the Ah-7 Lynx, and his staff Andy & Frank were incredibly kind and helpful during the whole 3D scanning process. During the so-called “free days”, based on the request of the client, I was on a visit to the museums for potential new projects. After returning home from the 3D scanning, I began to process all the data.

This 3D scanning shoot was incredibly valuable in knowledge, many new techniques were tested and implemented into my new workflow.

I am happy with my new workflow, and the results of the new 3D scanning workflow are stunning.